Adhesives And Sealants Mixers

Monitoring of Quality in Commercial-Grade Sealants and Adhesive Mixers

Depending on the adhesive composition, raw materials, and production methods, adhesive mixers are widely used in a variety of configurations. Adhesive mixer designs with high viscosity and solid suspensions provide the most challenges. We can ensure the quality of your adhesives and sealants since we have established our adhesive mixing expertise with some of the top adhesive manufacturers.

Custom Configured Mixers

Assure The Quality Of Your Adhesives & Sealants

The quality of the final product is directly impacted by the consistency of your sealants or adhesives during the procedure. Adhesive mixers are required to ensure that your product meets all specifications throughout the process.

Premix is unique in that it lets you control this quality by getting inside your end users' properties.

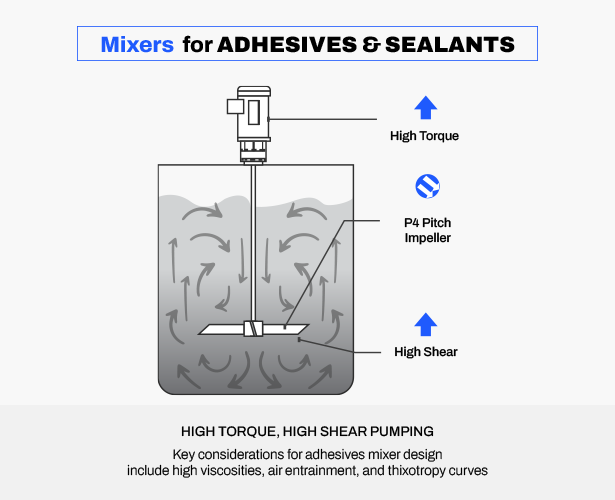

Restoring glue to specification or homogeneity after initial manufacture is one of the adhesive mixers' biggest issues. A conventional high-speed mixer produces non-directional, localized mixing; thus, avoid using one for this purpose. We have the special setups and knowledge to handle these and other obstacles. When constructing a mixer for adhesives and sealants, issues like air entrainment and tank cleaning are crucial considerations.

Use Premix's high-torque, high-pumping adhesive agitator to solve homogeneity problems; they are designed for durable, high-viscosity mixing.

An axial flow pattern to guarantee that the product meets specifications.

Mixers for Sealants and Adhesives—Customized for Your Procedure

The talented adhesive and sealant mixing specialists at Premix work hard to comprehend your workflow, choose the ideal mixer, and provide you with a comprehensive mixing solution. Our ability to customize mixers for your application and ensure the cycle time and consistency of your product comes from our expertise in your process.

What was the outcome? Uniformity.