Chemical mixer and agitator

Chemical mixers should be designed specifically for your application and process. A one-size-fits-all approach minimizes the importance of mixing in the product or process control.

Batch Chemical Mixing: A Tailored Approach

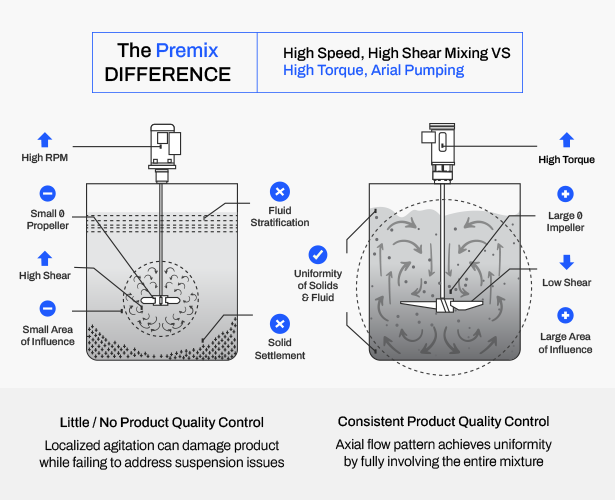

Batch chemical mixing, often overlooked, presents a powerful opportunity for optimized processes. Premix frequently steps in to replace ill-suited mixers – those installed without proper consideration for the tank, chemical process, or the critical quality control requirements of the final product mixture. This is precisely why we offer one of the most configurable product lines available. We believe in a solution-oriented approach, rejecting the limitations of "one-size-fits-all" mixing. Our team collaborates closely with your representatives to configure and optimize a chemical mixer that perfectly aligns with your specific needs.

The Power of Batch Chemical Mixing: A Tailored Approach

Batch chemical mixing, often overlooked, offers a powerful and versatile approach to optimizing processes. Premix frequently steps in to replace mixers that were installed without proper consideration for the tank, chemical process, or critical quality control requirements for the final product mixture. This highlights the importance of a tailored solution.

PREMIX SOLUTION:

Premix Technologies: Unleashing the Power of Precision in Industrial Chemical Mixing

Don't settle for "good enough" mixing. In industrial chemical processing, precise mixing is the cornerstone of quality control and efficient production. At Premix Technologies, we understand that a one-size-fits-all approach doesn't cut it. we engineer custom mixing solutions tailored to your unique industrial chemical and process requirements.

Experience Our agitator Difference :

- Customized Solutions: Our team of experts collaborates closely with you to understand your needs, from tank design and chemical properties to desired mixing quality and energy efficiency goals.

- Our agitators are built to outperform. We don't just offer high-RPM mixing; we focus on delivering optimal results through strategically engineered torque for thorough and efficient mixing.

- Industry-Leading Support: Invest in peace of mind. Our agitator comes with industry-leading warranties and comprehensive support services to ensure your equipment operates at peak performance for years to come.

- Ready to unlock the full potential of your chemical mixing processes? Contact Premix Technologies today. Submit a quote request to discuss your project with our professionals and receive a prompt and competitive quote.

Together, let's engineer a proper mixing solution that optimizes your processes helps to maximize quality, and minimizes energy consumption.

Custom Configured Mixers