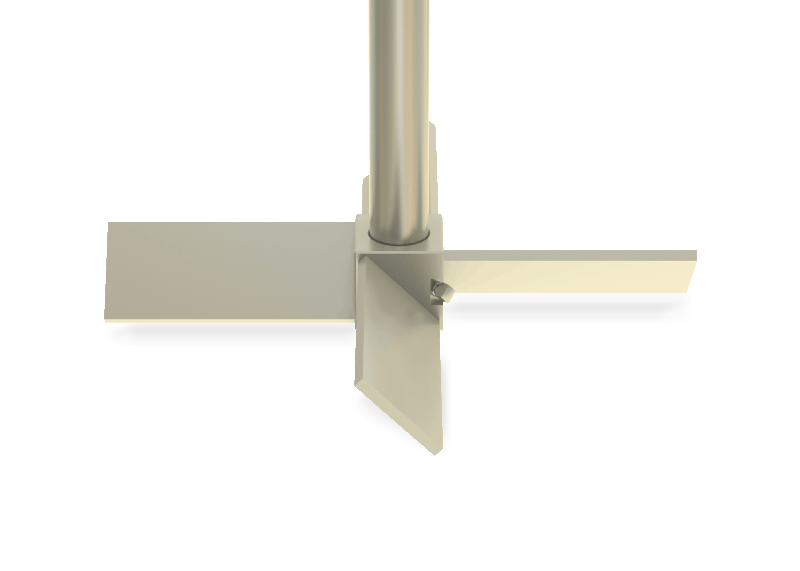

| Impeller Type | Central / off center Baffles: 0 / 2 / 3 / 4 Blades: 2 / 3 / 4 Stages: 1 |

|---|---|

| Flow Direction | Upward |

| Preferred Arrangement | Center Mounted |

| Blending | • • • |

| Suspending | • • • |

| Dispersing | • • |

| Heat Transfer | • • • |

| Gassing | • • |

| Flow Range | Turbulent / Transitional |

| Viscosity Range | 1 - 50,000 |

| Features | - Universal mixing impeller for a wide viscosity range - Variable blade angles (standard versions with 30° and 45°) |

| Diameter Ratio | 0.5 – 0.8 [d1 / d2] |

| Speed | 300 – 1500 |

| Tip Speed | 5 − 20 [ft/s] |

Turbine agitators, also known as radial flow impellers, are a common type of impeller used in various industrial mixing applications. They are characterized by their multiple flat blades extending radially from a central hub. Here are some key features of turbine agitators:

- 01. Radial Flow

- 02. High Flow Rate

- 03. Moderate Shear

- 04. Versatility

- 05. Low Viscosity Applications

- 06. Broad Impeller Diameter Range

- 07. Minimal Baffling Requirements

- 08. Easy Installation and Maintenance

- 09. Low Power Consumption

Overall, turbine agitators offer a balanced combination of flow characteristics, moderate shear, and versatility, making them a popular choice for various mixing applications across different industries. However, the specific suitability of a turbine agitator for a given process depends on the fluid properties, process objectives, and vessel geometry, which should be carefully evaluated during the agitator selection process.

Turbine agitators, also known as radial flow agitators, are widely used in various industries for their specific advantages in certain applications. The design of turbine agitators allows them to generate radial flow patterns, which can be beneficial in achieving certain mixing objectives. Here are some of the key uses of turbine agitators in different industries:

- 01. Chemical Industry

- 02. Petrochemical Industry

- 03. Water and Wastewater Treatment

- 04. Mining and Metallurgy

- 05. Food and Beverage Industry

- 06. Pharmaceuticals and Biotechnology

- 07. Paints and Coatings

- 08. Pulp and Paper Industry

- 09. Adhesives and Sealants

- 10. Renewable Energy Production

It's essential to consider the specific mixing requirements, fluid properties, and vessel geometry when selecting an agitator type for an industrial process. While turbine agitators excel in certain applications, other impeller types may be more suitable for different processes. Additionally, the scale and design of the agitator should be tailored to match the unique needs of each industrial application.

Computational Fluid Dynamics (CFD) analysis for an agitator involves simulating and analyzing the flow of fluids and the associated mixing behavior within a mixing vessel or tank equipped with an agitator. This analysis is crucial in industries such as chemical engineering, pharmaceuticals, food processing, and more, where efficient mixing and agitation are essential processes.

Our step-by-step approach to conducting a CFD analysis for an agitator:

- 01. Problem Definition and Geometry Creation

- 02. Mesh Generation

- 03. Boundary Conditions

- 04. Solver Setup

- 05. Simulation Run

- 06. Post-processing and Analysis

- 07. Optimization and Iteration

- 08. Reporting and Documentation