| Sr. No. | Pump Model | Capacity Max (LPH) | Pressure Max (Kg/cm2) |

|---|---|---|---|

| 1 | PRPL - 1 | 250 | 90 |

| 2 | PRPL - 2 | 850 | 90 |

| 3 | PRPL - 3 | 3000 | 225 |

| 4 | PRPL - 4 | 7000 | 270 |

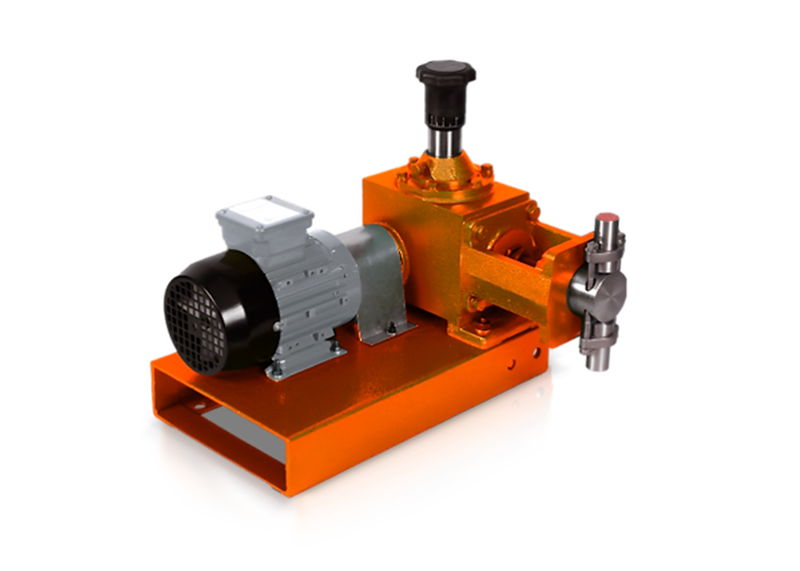

Plunger dosing pumps, also known as reciprocating pumps, are positive displacement pumps that are commonly used in various industrial applications. These pumps are designed to deliver precise and accurate dosages of liquids or chemicals. Here are some key features of plunger dosing pumps:

- 01. Positive Displacement

- 02. Reciprocating Action

- 03. Adjustable Flow Rate

- 04. High Pressure Capability

- 05. Chemical Compatibility

- 06. Precision Dosing

- 07. Low Maintenance

- 08. Stroke Length Adjustment

- 09. Pulsation Dampeners

- 10. Manual or Automated Control

It's important to select the right plunger dosing pump for your specific application, considering factors such as the required flow rate, pressure, chemical compatibility, and the level of precision needed in dosing. Always refer to the manufacturer's specifications and guidelines for proper installation, operation, and maintenance of the dosing pump.

Plunger dosing pumps, also known as reciprocating pumps, are widely used in various industries for their accurate and precise dosing capabilities. These pumps work on the principle of a reciprocating plunger or piston that moves back and forth to displace a fixed volume of fluid with each stroke. Here are some common applications of plunger dosing pumps in different industries:

- 01. Water Treatment

- 02. Chemical Industry

- 03. Oil and Gas

- 04. Food and Beverage Industry

- 05. Pharmaceuticals

- 06. Pulp and Paper Industry

- 07. Textile Industry

- 08. Printing Industry

- 09. Agriculture and Irrigation

- 10. Cleaning and Sanitization

- 11. Automotive Industry

- 12. Boiler Feed and Water Treatment

Plunger dosing pumps are preferred in these industries for their accurate and reliable dosing capabilities, which ensure consistent and controlled delivery of fluids. Their ability to handle a wide range of chemicals and provide precise flow control makes them essential tools in industrial processes requiring accurate dosing and metering.