WATER TREATMENT AGITATOR

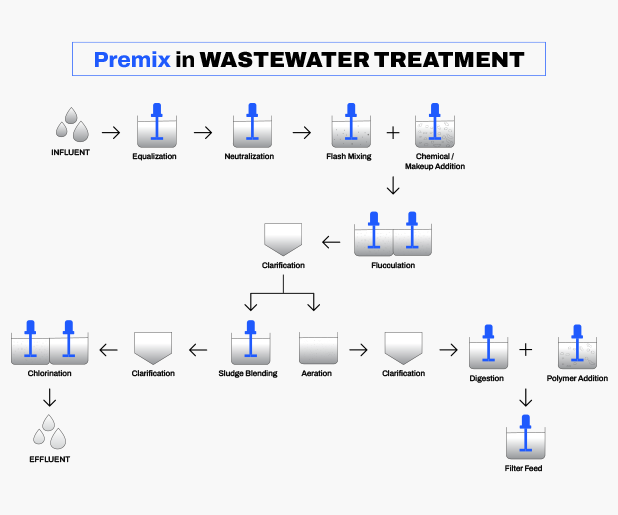

A Complex Sequence Of Processes And Reactions Sets Up The Process Of Treating Water.

Wastewater treatment relies on a symphony of interconnected stages. Each step builds on the success of the last, shaping how we design custom mixers for you. Our goal? Optimal quality and efficient management throughout your entire process. Years of expertise ensure our mixers tackle the specific challenges of your unique treatment procedures.

Precise mixing control is paramount, from flash mixing to polymer addition. We understand different chemicals have diverse needs. Some require complete dissolution, while others, like lime slurries, demand in-depth knowledge of solids handling, mass transfer, and crucial neutralization reactions.

New and old wastewater treatment processes, including Moving Bed Bio-Reactors (MBBRs), and aerobic and anaerobic systems, all rely on controlled mixing for optimal performance. Our expertise in mixing solutions allows these processes to leverage the energy efficiency benefits of top-entry mixers. Submersible mixers, air spargers, and other methods are often less efficient and should be considered alternatives to, rather than the default choice for, wastewater treatment applications. Premix can achieve this, but others cannot. Top-entry mixers are uncommon in these regions, typically because other mixer manufacturers do not manage their mixing. However, correct Industrial mixer design will assist you in controlling mixing in these areas and provide substantial cost reductions over more popular air flotation or submersible mixers.

PREMIX SOLUTION:

Don't settle for just any mixer. Our deep understanding of water and wastewater treatment processes allows us to custom-configure high-torque, high-flow industrial mixers that perfectly match your needs. Whether you require mixers that meet stringent G-value standards or need solutions for tanks with unique geometries, we have the expertise to deliver. Get a quick quote for your wastewater mixer needs or speak with an application engineer – simply submit a request today!

Customized Agitator and mixer manufacture for water treatment plant.

Moving Bed Biofilm Reactor (MBBR) Mixing Solutions

Premix offers efficient mixing configurations for anoxic and aerobic zones in your MBBR. Our systems utilize gear reducers with VFDs and robust, high-torque, low-speed motors to accommodate various tank depths.

The impeller design determines the flow direction and pumping power required within the tank. Our innovative stainless steel MBBR impeller achieves thorough media movement and biofilm floc formation, mimicking the action of air diffusers but at significantly lower energy costs. This translates to operational savings for your wastewater treatment facility.

Sludge Blending Challenges

Sludge blending is another area where the wastewater industry faces difficulties in achieving the high efficiencies offered by top-entry mixers. Inadequate mixing control from some manufacturers has led to inefficiencies in sludge applications.

During treatment and dewatering, sludge from primary and secondary clarifiers goes through centrifuges, belt filter presses, anaerobic sludge tanks, and holding tanks. Agitation is crucial throughout this process to ensure a homogenous mixture. Mixers are essential in sludge tanks for two key functions: blending in chemical additives for more effective dewatering and maintaining homogeneity by preventing solids from settling.

We will demonstrate this process for you at Premix, and we'll make sure your controlled mixing environment reaps the benefits of a top-entry mixer's efficiency and energy savings.