Agitator and Mixer for Oil and Gas Industries

MIXING OF OIL AND GAS WIH PREMIX AGITATOR

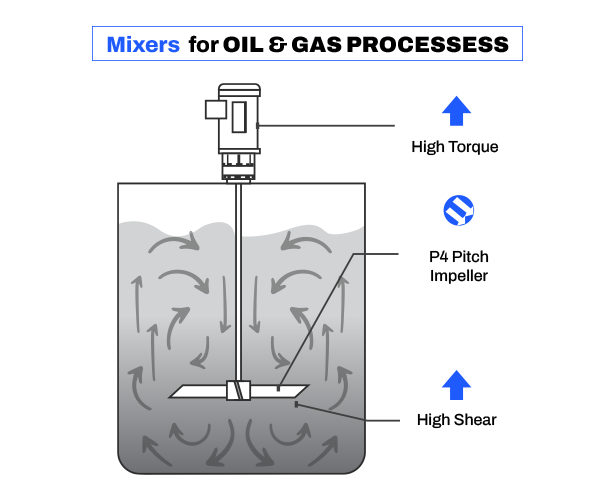

The petroleum and oil industries rely heavily on well-designed agitators. These mixers are usually classified as side entry mixers or top entry agitators.

Additionally, these mixers will work in tandem with the extraction equipment—such as mixers for fracturing chemicals or drilling mud—as well as the holding tanks and processing phases of the oil and gas process.

Energy savings can be achieved by being aware of when to use a side entry mixing device. A holding tank's capacity to assist suspend sludge will decide how efficient this operation is all along. There has never been a more important choosing process for industrial mixers for oil and gas.

Our chemical and mechanical engineers will create and guarantee a mud mixer and the time it takes to bring that into uniformity, regardless of your chemical makeup.

For your needs, Premix offers a complete range of durable industrial oil and petroleum mud mixers, suitable for mixing fracking fluids, drilling muds, asphalt, crude oil, and gasoline.

Our powerful industrial agitators may be set up to precisely process any liquid application. Although Premix takes pride in its technological ingenuity, our real contribution to you is our thorough understanding of your liquid and its intended use.

Premix Oil & Gas Mixing Expertise: Optimizing Your Workflow

Our oil and gas mixing specialists at Premix are committed to understanding your workflow, selecting the optimal mixer, and delivering a comprehensive mixing solution. Through a thorough understanding of your process, including viscosity, density, tank design, and desired blending time, we can create custom-designed mixers to perfectly meet your needs. Our extensive experience allows us to offer Solution Assurance, which helps you determine process uniformity and cycle time.

The result? Predictable Uniformity, Delivered.

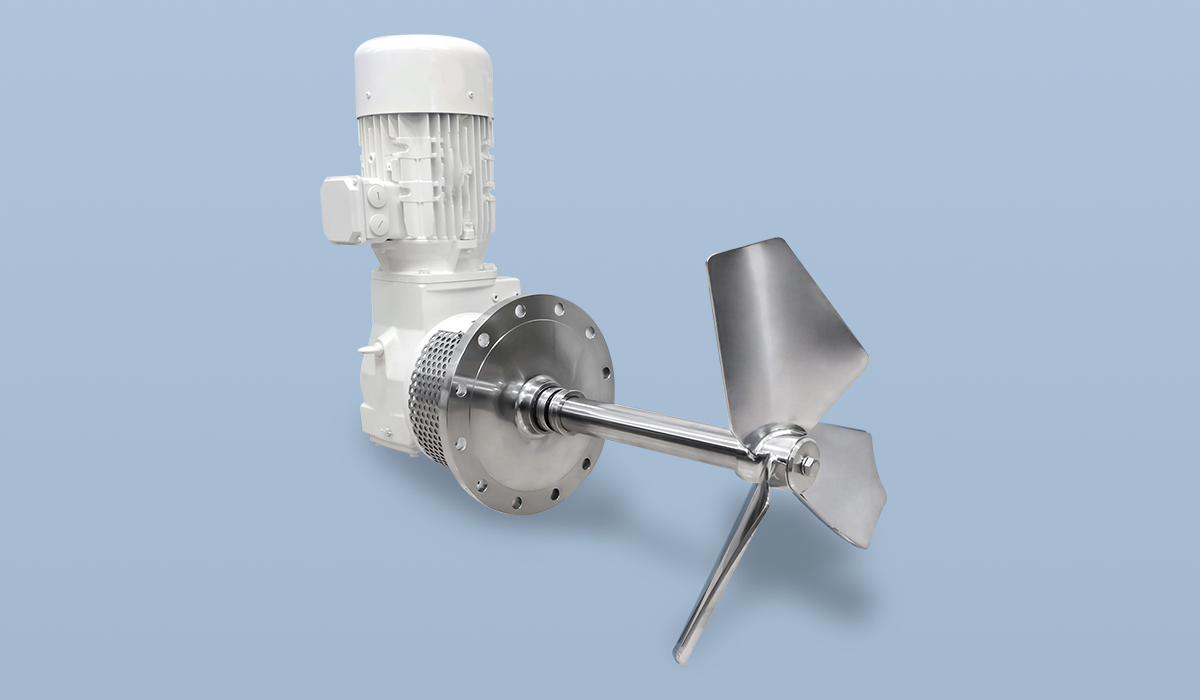

PREMIX Side Entry Agitator

For your mining and refining project, collaborate with our mining mixer specialists to create a robust mixer that can handle a variety of tasks, such as ore leaching, flotation, conditioning, attrition scrubbing, and counter current decantation.

Motor Range

HP range - 1 HP to 75 100HP

Mounting - Flanged

Efficiency Class - IE2/IE3

Gearbox - Standard RPM range.

S.F - 1.5 Minimum

Mounting - Flanged